Specialist at machining

DSM AS is a company specialized in rapid response machining.

We therefore have a variety of other in-house services, as sawing, cold root rolling, hardness testing, NDT, shot peening, glass blasting, etc.

We also have a large network of extremely dedicated partners/suppliers that helps us whit services like deep hole boring, EDM, hardening, nitriding, HVOF, hard facing, cladding, licence threads, gas/plasma/water cutting, surface treatment such as phosphate, xylan, painting etc. All services are performed to familiar International standards and/or special procedures.

Contact:

DSM AS

Skurvebakkane 22

4331 Ålgård

Norway

+47 950 59 945

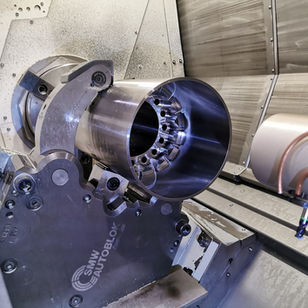

We perform CNC machining in a state-of-the-art machine park, with the best tools on the market. Our employees are experts in advanced machining, highly dedicated and experienced.

This resulting in that we produce products of the very highest quality fast and efficiently.

Our employees also monitor the products throughout the organization, which means that we have extreme control over the entire processes and minimize the chances of deviations.

These are some of the reasons why we work efficiently and cost-consciously, so we are extremely fast and competitive..

Production

Machines and equipment

CNC Machine 1

Mazak IG 400 x 2500mm

Produced 08-2013

- Max swing Ø760mm

- Max lenght 2500mm

- Hole through spindle Ø102mm

- Chuck Ø315mm

- Simultaneous 5 axis

- 80 plcs tool magazine

- Work rest Ø52-Ø380

- 70 Bar high pressure coolant

- Renishaw probe

CNC Machine 2

Mazak IG I450H x 2500mm

Produced 09-2021

- Max swing Ø810

- Max lenght 2500mm

- Hole through spindle Ø102mm

- Chuck Ø315mm

- Simultaneous 5 axis

- 112 plcs tool magazine

- Work rest Ø35-Ø340

- 70 Bar high pressure coolant

- Renishaw probe

- 3 plcs long tool stocker (1m)

GibbsCAM

- Full package, simultaneous 5 axis, volumill, 3D,etc.

MazaCAM

- Editor and CAD-import

SAW

MEBA 560A

- Cuts up to Ø560mm Round and 560x700 Rectangular

Materials

We have a large network of suppliers that's supping us with high quality material to a large variety specs and standards.

We also hold large stock of high quality materials, to be able to deliver fast and predictably.

- AISI 4140 80ksi conforming to API 7-1 / API 6A / NACE MR 0175 (Ø2-Ø12,25'')

- AISI 4145 110ksi conforming to API 7-1 / API 6A (Ø2-Ø12,25'')

- AISI 4145 125ksi conforming to API 7-1 / API 6A (Ø2-Ø10'')

- AISI 4330 150ksi conforming to API 7-1 / API 6A / (Ø2,5-Ø8,75'')

- Tubes and bored bars in different dimensions and qualities, according to NACE MR 0175, API 6A, API 5CT etc.

- Alloy 718 (Inconel 718) conforming to API 6A (Ø0,625-Ø2,5'')

- Alloy 500 (Monell K-500) conforming to API 6A (Ø1,75-Ø2,5'')

- Aluminium 6082 - T6 (Ø16-Ø320mm)

Threads

We hold a variety software, gauges and equipment for different types of special threads as

- API NC according to API spec 7

- API REG according to API spec 7

- API FH according to API spec 7

- API Sharp-tread tubing: Non-upset (NUE) and External-upset (EUE) according to API spec 5A and B (Sharp vee) (Sharp EU)

- PAC

- Rachet and butress

Cold root rolling

We have equipment and procedures to cold root roll thread forms as,

V0.038 / V0.040 / V0.050 and H90

Our equipment can apply up to 8 tons of force.

Shot peening

We also have equipment and procedures to shot peen threads or other geometres.

Shot peening is typically used to induce residual surface compressive stresses in metal parts to increase fatigue strength and resistance to stress-corrosion cracking.

Gallery

Are you our new CNC operator?

Are you ambitious and hungry for new challenges? Do you want to work in a small solid company in strong growth?

We are looking for a CNC operator who enjoys a very varied production and at times a hectic working day.

Tasks

- Operating CNC machine(s)

- Programming, Mazatrol, Mazacam, Gibbcam

- Tool rigging

- CNC machining

- Measurement and documentation of machined parts

- Daily maintenance of tools and machines

Tasks for those who are extra hungry

- Participate in the development of the company

- Participate in pricing and preparation of quotes

- Participate in planning, preparation and organization for production

- Purchase of tools, materials, services, etc.

- NDT and DT (PT, MT and hardness test)

Qualifications

- Good technical and practical understanding

- Good understanding of drawings and specifications

- Experience with complex parts and prototypes

- Minimum 3 years of experience with Integrex or other types of multifunction machines

- Programming experience (Experience with Mazatrol or Gibbscam is preferred)

- Good work ethic and engaged in the subject

- Reliable, cooperative and sociable

- Independent, efficient, structured and solution oriented

We offer

- Exciting and varied work tasks in and outside the machine, with both simple and complex parts as well as prototypes and small series

- Work in well-maintained modern machines, with a large selection of modern tools and software.

- Good opportunities for personal development

- Training

- Flexible working hours

- Pleasant and informal work environment in modern, pleasant and efficient premises

- Opportunity to develop and create your own workplace

- Canteen

- Competitive conditions

About us

DSM AS is a small solid company that consists of three higly skilled and experienced senior operators who have a burning interest in machining.

We have ambitions for further growth and therefore need more skilled operators on our team. We have a MAZAK IG 400x2500mm and a MAZAK IG I450Hx2500mm.

We dare say that we have some of the best machines, tools and software on the market.

The company has a solid economy, and we are keen to make good long-term investments in both operations and employees.

We are located in modern, pleasant and efficient premises at Skurve in Gjesdal business park.

Interested? Contact us at jobb@dsm-as.no, if you don't receive an answer in a few days, please check spam.

Interested and qualified? Text or call Daniel Seldal at tel. +47 950 59 945 for a non-committal chat.

News

11.02.2021

We have hired a highly skilled and dedicated senior CNC operator!

As well as we have ordered MAZAK INTEGREX i-450H x 2500mm

We are still considering to hire more operators to run skift on the machines.

If you are a highly skilled and dedicated CNC operator with Integrex experience, and are looking for new challenges, please contact us!

14.06.2021

Foundation for the new machine

The new machine arrived!

24.12.2021

New man on the team!

29.12.2021

We are glad to announce that we have signed a member to our team!